P29 Technology • Case Study

For more information please email Paul Rothman or Mark Holdsworth. Thank you.

Increasing the throughput of the global copper industry by as much as 25% to bridge the decade long 30% supply deficit being forecast

We are a trusted partner and technology innovator to the global mining industry……. Just ask one of the 450 mine sites that has our equipment installed

Our commitment to serving our mining customers in more than 46 countries drives our continual focus on delivering highly innovative process optimization solutions

We have earned the respect and trust of the mining industry with our process optimization solutions which can dramatically improve the throughput of an existing mining operation by up to 25%

The green transition will support a surge in copper demand – Copper demand is estimated to grow nearly 600% to 5.4 Mt by 2030 across Electric Vehicles, wind, solar and battery technology

The copper market is unprepared for this critical role – It is estimated that there will be a long -term supply gap of 8.2 Mt by 2030

Sticky supply threatens to deplete copper stocks by mid-decade – Copper is so integral to the green transition that supply requirements necessitate a spike in copper prices

Copper is on a necessary path to $15,000/ton – Copper prices as of May 7th (10,424/t) are too low to prevent a near-term risk of inventory depletion

Copper is key for electrification – Copper properties make copper the first-best affordable material for the use in cables, batteries, transistors and inverters-all key technologies on the path to net zero

Copper mine supply peaks in 2024 – After a 5-year period of essentially no growth in copper mine supply up to and including 2021. it is expected that mine supply will peak in 2024 at 24Mt before declining in 2026 and through 2030

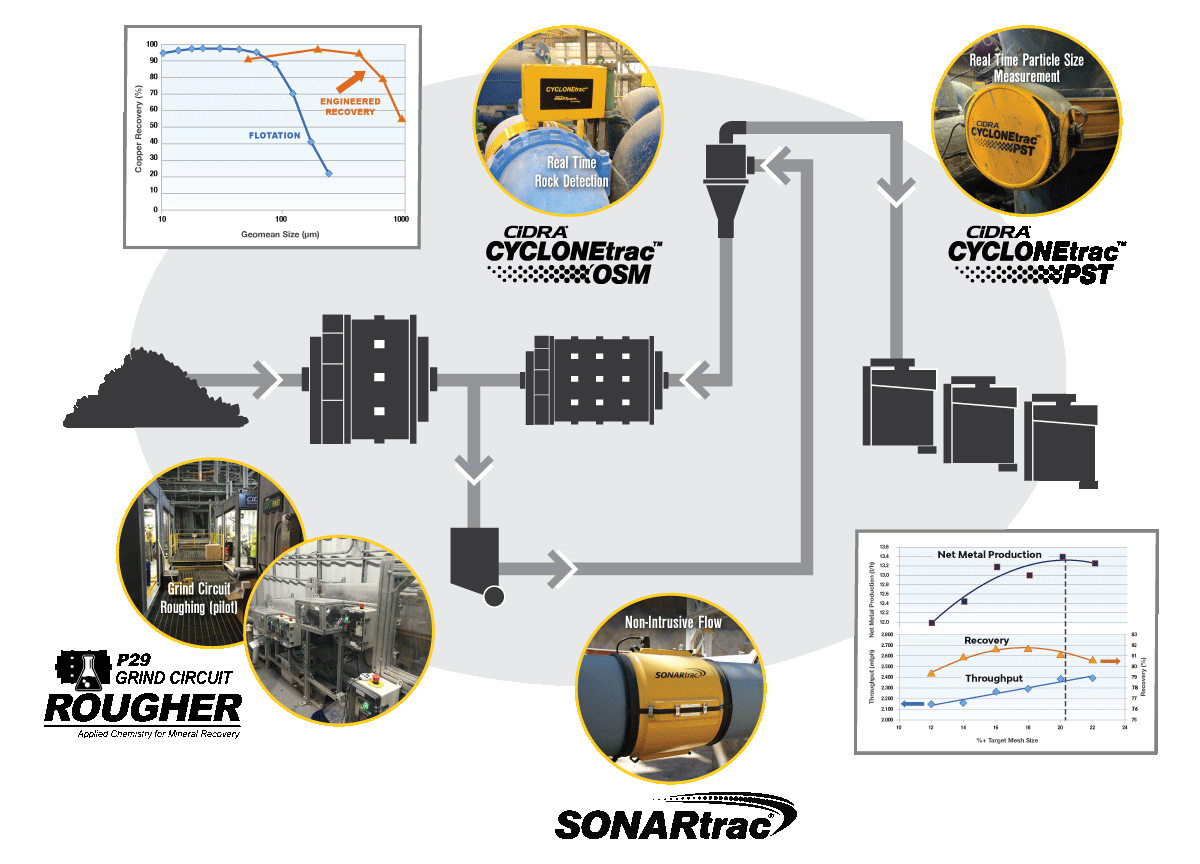

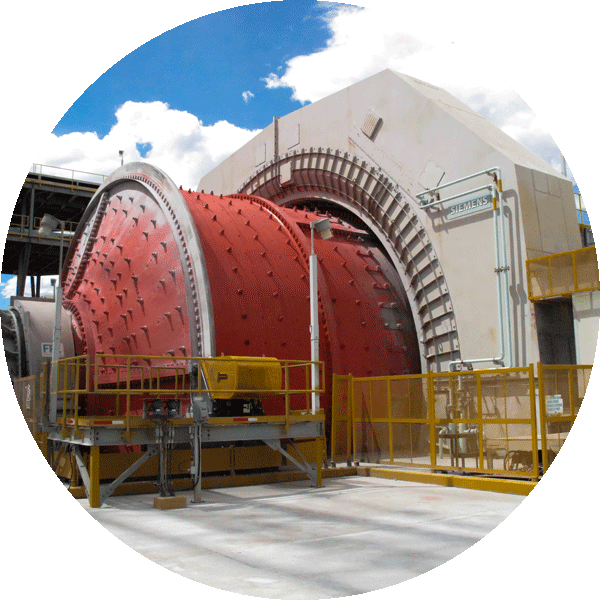

P29 represents an innovative approach to unlocking the capacity of existing grinding circuits through the application of coarse particle recovery

P29 dramatically improves the throughput and economics of an existing mine site without the cost of a new grind line

Bolt on functionality of P29 ensures compatibility with current chemical reagents in an efficient footprint

The P29 system lowers water usage significantly as well as enabling power reduction with the added benefit of delivering coarse particles for the construction of tailings dam walls.

P29 can be applied to all sulphide minerals and is versatile in its ability to selectively capture its targeted minerals. It is a natural complement to an existing mine site.

Copper is a critical component of decarbonization. Electric vehicles, batteries, energy storage, high voltage wiring, wind turbines and photovoltaics all use copper as a fundamental enabler.

CiDRA’s P29 systems makes it possible to produce copper in a more sustainable manner by using less electricity, and water per ton of ore produced.

P29 Mineral Separation systems generate a coarse particle based waste stream. This is ideal for the construction of a new generation of more stable, safer tailings dam walls.

CiDRA’s line of SONARtrac flow meters is a breakthrough in flow measurement technology. Our passive sonar flow meters provide accurate and reliable flow measurements for a wide range of applications and industries. Over the years, our family of SONARtrac systems has evolved to include a variety of flow meters designed to measure single and multiphase flows from water to highly aggressive slurries. Due to their non-contact design, our sonar flow meters do not have any moving parts or process wetted parts that are subject to wear, or inherent drift mechanisms. Instead, they install easily on the outside of any type of pipe and provide years of service with no maintenance required.

CiDRA Minerals Processing Inc. and OZ Minerals Ltd are pleased to announce that they have entered into a Memorandum of Understanding that provides a basis of common understanding to commission a Front End Engineering Design (FEED) study for customization and tie-in of CiDRA’s proprietary mineral separation technology for operation in a grind circuit rougher application at OZ Minerals’ Carrapateena Mine Site.

CiDRA Minerals Processing Inc. has a long history of applying a proven technology and science in a unique, robust architecture to enhance production efficiency and enhanced recovery in the mining sector. Customer challenges and unserved needs have fueled CiDRA’s mission and passion for ingenuity and innovation to develop industry specific product optimization solutions to mines throughout the world.

CiDRA Holdings has a twenty-year history of conceiving, developing and building leading edge companies and then spinning them out as standalone businesses. CiDRA Concrete Systems, Inc. (“CiDRA Concrete”) is the latest example of this proven business model in action. CiDRA Concrete, headquartered in Eden Prairie, Minnesota, is an IoT based business that provides real time data that continuously measures the concrete quality from the batch plant to the job site via concrete Ready-Mix trucks.

CEO and Founder CiDRA Minerals Processing, Inc.

Kevin Didden founded the company in 1996. Since that time, CiDRA has excelled at delivering innovative technology solutions to its customers as well as become a trusted process optimization company to many of the largest companies in the world. Kevin currently serves on the board of Directors for CiDRA and is the former Chairman of the CyVek Corporation. He spent a total of 9 years at United Technologies in the field of Technology Management. Kevin received a B.S. degree in Business Administration from the University of CT and an MBA from Rennsaeler Polytechnic Institute.

President, CiDRA Minerals Processing, Inc.

Paul Rothman serves as President of CiDRA’s Minerals Processing Business Unit. Paul has 25 years of product and business development experience. Prior to joining CiDRA Paul spent 16 years with United Technologies developing flight critical control systems for the aerospace industry. Paul holds a Bachelors Degree in Mechanical Engineering from the University of Notre Dame.

Vice President,

Chief Financial Officer

Gary Hokunson over 25 years of experience working with emerging growth companies with a heavy focus on operating and financial processes, mergers and acquisitions, business integrations and capital structure. Gary started his career in public accounting, including several years with Price Waterhouse. After leaving Price Waterhouse, he worked for a number of private equity backed companies in the healthcare, manufacturing, and services industries. He received his B.S. degree in accounting from Quinnipiac University.

Executive Vice President, Corporate Development and General Counsel

Mike Grillo is an attorney with venture capital, corporate finance and transactional experience. Prior to joining CiDRA, Mike focused on Intellectual Property protection, technology management and licensing with a private law firm and with a fortune 100 company. He received a Bachelors Degree in Electrical Engineering from the University of Delaware and a JD from the University of Connecticut School of Law.

Vice President Of Application Development

Mark Holdsworth is responsible for developing customer partnerships, managing applications, and the delivery of P29 technology to the mining industry. Working to develop the fundamentals, metallurgical performance, commercial design, construction, and operability of P29. With 24 years in mining, and 4 years in oil & gas, managing and leading surface operations in various global locations. Mark has a PhD in Chemical Engineering from University of Birmingham UK, aBEng(Hons) in Minerals Engineering from Camborne School of Mines UK.

Vice President,

CiDRA Minerals Processing, Inc.

Paul has 38 years of Project Engineering, Program Management, and Operations experience in Aerospace, Pulp and Paper, and Mining. His technology experience include controls, hydromechanical and electro-mechanical systems. 13 years at United Technologies Hamilton Standard Division focusing on Aerospace and 23 years at CiDRA focusing on industrial markets. At CiDRA Paul has been involved with product and technology development as well manufacturing and operations. Paul holds a BS in Electrical Engineering from the University of Connecticut.

Director, Business Dev

and App Engineering

Latin America

Bob Maron CiDRA’s Managing Director for Latin America. Bob pioneered the SONARtrac and CYCLONEtrac PST market in Latin America, being a part of the installation of the first SONARtrac meter in Chile. His areas of expertise and academic interest are: instrumentation systems for harsh environments; such as oil well drilling, mineral processing, and aerospace. As well as the designs of sensors and actuators. He is a Registered Professional Engineer who graduated from the University of Hartford. He also has an MS in Mechanical Engineering from Rensselaer Polytechnic Institute.

Client Services Manager,

Corporate Sales

Wendy Erickson is the Director, Client Services & Support. She manages the inside sales and customer support department. Wendy joined CiDRA in 1998 and has held various positions within the company. Prior to joining CiDRA, Wendy worked in finance at the state’s largest health insurer. Wendy holds an AS Degree from Quinnipiac University and has completed additional quality-related coursework at Rensselaer Polytechnic Institute.

Business Manager, Operations

Susan McCullough is responsible for managing SONARtrac sales, business operations CYCLONEtrac PST projects as well as service contracts in both Chile and Peru. Susan has a background in global sales, marketing, business development, personnel recruitment, and a specialization in Chilean markets. She has a Bachelor’s degree in International Relations with Honors from Michigan State University; a Master’s degree in Organizational Leadership, Project Management Emphasis with Distinction from Northern Arizona University

Director, Chemical Engineering

Michael Ryan 30 years of chemical product development. Focused on the development of P29 consumables chemistry, including the engineered polymeric media and the mineral release system. Having a diverse background in chemical products: including polymers in solid, liquid, emulsion, and microemulsion forms in the mining, paper, printing, and water-treatment sectors. Michael received a M.S. in PolymerChemistry from NYU; B.S. in Chemistry from the University of Connecticut.

Kevin Didden

CEO & Founder, CiDRA Minerals Processing, Inc.

David Huber

Chairman of the Board CiDRA Minerals

Founder and Chairman, Corvis Corporation

Svein Eggen

Chairman of the Board of Remedial Cyprus, Pcl

Daniel E. Levy

Managing Partner, Prince Capital Partners, LLC

Volker Mansfeld

Head of Corporate Development ALTANA AG

David Vogel

Managing Director, Velocity Equity Partners

Jaime E. Sepúlveda

Serves as Technical Consultant to Board

Founder & Executive Director, J-Consultants Ltd.

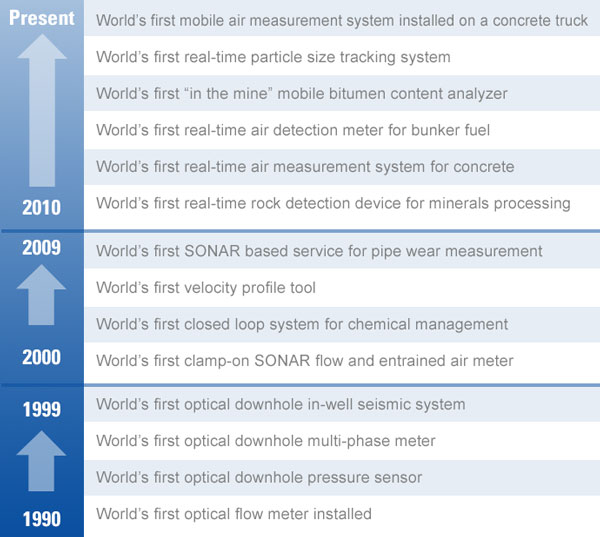

CiDRA is a leader in industry innovation, effectively combining the use of VC capital to spur innovation and generate IP, with directed funding from our customers to develop application-specific uses of new sensor technologies in critical industrial processes. CiDRA is known for strong IP creation, with over 700 U.S. and International patent and patent applications.

CiDRA has also created five companies in CT, sustaining jobs and growth as well as a US-based manufacturing facility. Three of those five companies were sold to multi-national, industry-leading companies – Weatherford, Illumina and Expro.

Below is a list of issued US Patents owned by or licensed to CiDRA. Many other patents are pending. CiDRA products and/or services may be covered by one or more of the below-listed US patents or foreign counterparts thereto. Please return to this site often to obtain the latest list of issued CiDRA US patents. You may obtain a copy of these patents from www.USPTO.gov.

| US Patent | Issue Date | Patent Title |

| 5,767,411 | 06/16/98 | Apparatus for Enhancing Strain in Intrinsic Fiber Optic Sensors and Packaging Same for Harsh Environments |

| 5,844,667 | 12/01/98 | Fiber Optic Pressure Sensor with Passive Temperature Compensation |

| 5,877,426 | 03/02/99 | Bourdon Tube Pressure Gauge with Integral Optical Strain Sensors for Measuring Tension or Compressive Strain |

| 5,892,860 | 04/06/99 | Multi-Parameter Fiber Optic Sensor for use in Harsh Environments |

| 5,925,879 | 07/20/99 | Oil and Gas Well Packer having Fiber Optic Bragg Grating Sensors for Downhole Insitu Inflation Monitoring |

| 5,945,665 | 08/31/99 | Bolt, Stud or Fastener having an embedded Fiber Optic Bragg Grating Sensor for Sensing Tensioning Strain |

| 5,973,317 | 10/26/99 | Washer having Fiber Optic Bragg Grating Sensors for Sensing a Shoulder Load between Components in a Drill String |

| 5,986,749 | 11/16/99 | Fiber Optic Sensing System |

| 5,987,197 | 11/16/99 | Array Topologies for Implementing Serial Fiber Bragg Grating Interferometer Arrays |

| 6,009,216 | 12/28/99 | Coiled Tubing Sensor System for Delivery of Distributed Mulitplexed Sensors |

| 6,016,702 | 01/25/00 | High Sensitivity Fiber Optic Pressure Sensor for use in Harsh Environments |

| 6,072,567 | 06/06/00 | Vertical Seismic Profiling System having Vertical Seismic Profiling Optical Signal Processing Equipment and Fiber Bragg Grafting Optical Sensors |

| 6,118,914 | 09/12/00 | Method and Device for Providing Stable and Precise Optical Reference Signals |

| 6,137,621 | 10/24/00 | Acoustic Logging System using Fiber Optics |

| 6,175,108 | 01/16/01 | Accelerometer Featuring Fiber Optic Bragg Grating Sensor for Providing Multiplexed Mulit-Axis Acceleration Sensing |

| 6,191,414 | 02/20/01 | Composite form as a component for a Pressure Transducer |

| 6,227,114 | 05/08/01 | Select Trigger and Detonation System using an Optical Fiber |

| 6,229,827 | 05/08/01 | Compression-Tuned Bragg Grating and Laser |

| 6,233,374 | 05/15/01 | Mandrel-Wound Fiber Optic Pressure Sensor |

| 6,249,624 | 06/19/01 | Method and Apparatus for Forming a Bragg Grating with High Intensity Light |

| 6,252,656 | 06/26/01 | Apparatus and Method of Siesmic Sensing Systems using Fiber Optics |

| 6,271,766 | 08/07/01 | Distributed Selectable Latent Fiber Optic Sensors |

| 6,274,863 | 08/14/01 | Selective Aperture Arrays for Seismic Monitoring |

| 6,278,811 | 08/21/01 | Fiber Optic Bragg Grating Pressure Sensor |

| 6,279,660 | 08/28/01 | Apparatus for Optimizing Production of Mulit-Phase Fluid |

| 6,298,184 | 10/02/01 | Method and Apparatus for Forming a Tube-Encased Bragg Grating |

| 6,305,227 | 10/23/01 | Sensing Systems Using Quartz Sensors and Fiber Optics |

| 6,310,990 | 10/30/01 | Tunable Optical Structure Featuring Feedback Control |

| 6,317,555 | 11/13/01 | Creep-Resistant Optical Fiber Attachment |

| 6,321,007 | 11/20/01 | Optical Fiber Having a Bragg Grating Formed in Its Cladding |

| 6,338,579 | 01/15/02 | Fiber Optic Sleeve Assembly for use at a Splice Junction of a Fiber Optic Cable |

| 6,346,702 | 02/12/02 | Fiber Bragg Grating Peak Detection System and Method for Doing the Same. |

| 6,351,987 | 03/05/02 | Fiber Optic Pressure Sensor for DC Pressure and Temperature |

| 6,354,147 | 03/12/02 | Fluid Parameter Measurement in Pipes using Acoustic Pressures |

| 6,363,089 | 03/26/02 | Compression-Tuned Bragg Grating and Laser. |

| 6,403,949 | 06/11/02 | Method and Apparatus for Correcting Systematic Error in a Wavelength Measuring Device. |

| 6,404,961 | 06/11/02 | Optical Fiber Cable having Fiber in Metal Tube Core with Outer Protective Layer |

| 6,414,303 | 07/02/02 | High Accuracy Bragg Grating Based Pressure Sensor with Dual Resolution Mode |

| 6,422,084 | 07/23/02 | Bragg Grating Pressure Sensor |

| 6,435,030 | 08/20/02 | Measurement of Propagating Acoustic Waves in Compliant Pipes |

| 6,439,055 | 08/27/02 | Pressure Sensor Assembly Structure to Insulate a Pressure Sensing Device from Harsh Environments |

| 6,443,226 | 09/03/02 | Apparatus for Protecting Sensors within a Well Environment. |

| 6,445,868 | 09/03/02 | Optical Fiber Feedthrough Assembly and Method of Making Same |

| 6,448,551 | 09/10/02 | Fiber Bragg Grating Sensor System having Enhanced Strain-to-Wavelength Responsivity by using a Spectral Beating Based Vernier Effect |

| 6,450,037 | 09/17/02 | Non-Instrusive Fiber Optic Pressure Sensor for Measuring Unsteady Pressures within a Pipe. |

| 6,452,667 | 09/17/02 | Pressure-Isolated Bragg Grating Temperature Sensor |

| 6,453,108 | 09/17/02 | Athermal Bragg Grating Package with Coarse and Fine Mechanical Tuning. |

| 6,456,771 | 09/24/02 | Optical Fiber with a Pure Silica Core Having a Bragg Grating Formed in its Core and a Process for Providing Same. |

| 6,462,329 | 10/08/02 | Fiber Bragg Grating Reference Sensor for Precise Reference Temperature Measurement. |

| 6,463,813 | 10/15/02 | Displacement Based Pressure Sensor Measuring Unsteady Pressure in a Pipe |

| 6,466,716 | 10/15/02 | Optical Fiber Having a Bragg Grating in a Wrap that Resists Temperature induced changes in Length. |

| 6,470,036 | 10/22/02 | Tunable External Cavity Semiconductor Laser Incorporating Tunable Bragg Grating. |

| 6,490,931 | 12/10/02 | Fused Tension-Based Fiber Grating Pressure Sensor |

| 6,496,625 | 12/17/02 | Transmission Cable Optical Fiber Protector and Method |

| 6,501,067 | 12/31/02 | Apparatus for Protecting Sensing Devices |

| 6,507,693 | 01/14/03 | Creep-Resistant Optical Fiber Attachment. |

| 6,519,388 | 02/11/03 | Tube-Encased Fiber Grating |

| 6,526,212 | 02/25/03 | Optical Fiber Bulkhead Feedthrough Assembly and Method of Making Same. |

| 6,529,923 | 03/04/03 | Method for Improving the Accuracy in the Determination of a Waveform Center |

| 6,536,291 | 03/25/03 | Optical Flow Rate Measurement Using Unsteady Pressures |

| 6,550,342 | 04/22/03 | Circumferential Strain Attenuator |

| 6,558,036 | 05/06/03 | Non-Contact Temperature Sensor For Measuring Internal Temperature of Fluids Within Pipes |

| 6,563,968 | 05/13/03 | Tunable Optical Structure Featuring Feedback Control |

| 6,575,033 | 06/10/03 | Highly Sensitive Accelerometer |

| 6,587,798 | 07/01/03 | Method and System for Determining the Speed of Sound in a Fluid within a Conduit |

| 6,594,081 | 07/15/03 | Actuator Mechanism for Tuning an Optice Device |

| 6,594,288 | 07/15/03 | Tunable Raman Laser and Amplifier |

| 6,594,410 | 07/15/03 | Wide Range Tunable Optical Filter |

| 6,597,711 | 07/22/03 | Bragg Grating based laser |

| 6,601,411 | 08/05/03 | Method for Annealing an Optical Waveguide Having a Bragg Grating |

| 6,601,458 | 08/05/03 | Distributed Sound Speed Measurements for Multiphase Flow Measurement |

| 6,601,671 | 08/05/03 | Method and Apparatus for Seismically Surveying an Earth Formation in Relation to a Borehold |

| 6,609,069 | 08/19/03 | Method and Apparatus for Determining the Flow Velocity of a Fluid within a Pipe |

| 6,621,957 | 09/16/03 | Temperature Compensated Optical Device |

| 6,626,043 | 09/30/03 | Fluid Diffusion Resistent Glass-Encased Fiber Optic Sensor |

| 6,633,695 | 10/14/03 | Compression-Tuned Grating Based Optical Add/Drop Multiplexer |

| 6,668,656 | 12/30/03 | Optical Sensor having Differing Diameters |

| 6,685,361 | 02/03/04 | Fiber Optic Cable Connections for Downhole Applications |

| 6,690,866 | 02/10/04 | Optical Fiber Cable for use in Harsh Environments |

| 6,691,584 | 02/17/04 | Flow Rate Measurement Using Unsteady Pressures |

| 6,698,297 | 03/02/04 | Venturi Augmented Flow Meter |

| 6,732,575 | 05/11/04 | Fluid Parameter Measurement in Pipes Using Acoustic Pressures |

| 6,753,034 | 06/22/04 | Method of Metallization of an Optical Waveguide |

| 6,763,043 | 07/13/04 | Tunable Grating Based Dispersion Compensator |

| 6,768,825 | 07/27/04 | Optical Sensor Device Having Creep-Resistant Optical Fiber Attachments. |

| 6,776,045 | 08/17/04 | Bragg Grating Pressure Sensor for Industrial Sensing Applications. |

| 6,782,150 | 08/24/04 | Apparatus for Sensing Fluid In a Pipe |

| 6,785,004 | 08/31/04 | Method and apparatus for interrograting fiber optic sensors |

| 6,789,424 | 09/14/04 | Highly sensitive accelerometer |

| 6,792,009 | 09/14/04 | Tunable Grating-Based Channel Filter Parking Device. |

| 6,804,693 | 10/12/04 | Method for Reducing Skew in a Real-time Centroid Calculation. |

| 6,810,178 | 10/26/04 | Large diameter optical waveguide having blazed grating therin |

| 6,813,013 | 11/02/04 | Pressure isolated bragg grating temperature sensor |

| 6,813,962 | 11/09/04 | Distributed sound speed measurements for multiphase flow measurement |

| 6,820,489 | 11/23/04 | Optical differential pressure sensor |

| 6,826,343 | 11/30/04 | Large diameter multi core waveguide |

| 6,834,142 | 12/21/04 | Optical grating based filter |

| 6,837,098 | 01/04/05 | Sand monitoring within wells using acoustic arrays |

| 6,840,114 | 01/11/05 | Housing on the exterior of a well casing for fiber sensors |

| 6,856,729 | 02/15/05 | Wavelength monitor utilizing a tunable bragg grating and blazed grating |

| 6,862,920 | 03/08/05 | Fluid Parameter Measurement in Pipes using acoustic pressures |

| 6,865,194 | 03/08/05 | Strain Isolated Bragg Grating Temperature Sensor |

| 6,868,737 | 03/22/05 | Circumferential strain attenuator |

| 6,877,378 | 04/12/05 | Fluid Diffusion resistant glass-encased fiber optic sensor |

| 6,888,972 | 05/03/05 | Multiple component sensor mechanism |

| 6,889,562 | 05/10/05 | Flow Rate Measurement for industrial sensing applications using unsteady pressures |

| 6,891,621 | 05/10/05 | Highly sensitive cross axis accelerometer |

| 6,898,338 | 05/24/05 | A Fabry-Perot element based on a large-diameter optical waveguide |

| 6,898,541 | 05/24/05 | Method and apparatus for determining component flow rates for a multi-phase flow |

| 6,915,048 | 07/05/05 | Fabry-perot filter/resonator |

| 6,922,277 | 07/26/05 | Optical interleaver/deinterleaver device having an array of mirco-mirrors |

| 6,934,069 | 08/23/05 | Chromatic dispersion compensation device having an array of micromirrors |

| 6,947,640 | 09/20/05 | Alignment and imaging system for writing bragg gratings |

| 6,955,085 | 10/18/05 | Optical Accelerometer or displacement device using a flexure system |

| 6,956,687 | 10/18/05 | Optical blocking filter having an array of micromirrors |

| 6,957,574 | 10/25/05 | Well integrity monitoring system |

| 6,959,604 | 11/01/05 | Non-Contact fiber optic pressure sensor for measuring unsteady pressures in a pipe |

| 6,971,259 | 12/06/05 | Fluid density measurement in pipes using acoustic pressures |

| 6,982,996 | 01/03/06 | Large diameter optical wave guide, grate and laser |

| 6,986,276 | 01/17/06 | Deployable mandrel for downhole measurements |

| 6,988,411 | 01/24/06 | Fluid parameter measurement in pipes using acoustic pressures |

| 6,995,352 | 02/07/06 | Fiber optic based method and system for determining and controlling position of a sliding sleeve valve |

| 6,996,316 | 02/07/06 | Large diameter D-shaped waveguide and optical coupler |

| 7,006,206 | 02/28/06 | Method and apparatus for detecting peaks in an optical signal using a cross-correlation filter |

| 7,013,729 | 03/21/06 | Highly sensitive accelerometer |

| 7,019,883 | 03/28/06 | Dynamic optical filter having a spatial light modulator |

| 7,028,538 | 04/18/06 | Sand monitoring within wells using acoustic arrays |

| 7,028,543 | 04/18/06 | System and method for monitoring performance of downhole equipment using fiber optic based sensors |

| 7,032,432 | 04/25/06 | Apparatus and method for measuring parameters of a mixture having liquid droplets suspended in a vapor flowing in a pipe |

| 7,052,185 | 05/30/06 | Fiber optic cable connectors for downhole applications |

| 7,058,549 | 06/06/06 | Apparatus and method for measuring unsteady pressures within a large diameter pipe |

| 7,059,171 | 06/19/06 | Fluid density measurement in pipes using accoustic pressures |

| 7,059,172 | 06/13/06 | Fluid density measurement in pipes using accoustic pressures |

| 7,062,126 | 06/13/06 | Large diameter optical waveguide having bragg grating and being configured for reducing the bulk modulus of compressibility |

| 7,062,976 | 06/20/06 | An apparatus and method for measuring gas volume fraction of a fluid flowing within a pipe |

| 7,068,897 | 06/27/06 | Method for restoring or increasing photosensitivity in hydrogen or deuterium loaded large diameter optical waveguide |

| 7,080,529 | 07/25/06 | A method for making large diameter optical waveguide having bragg grating and being configured for reducing the bulk modulus of compressibility |

| 7,086,278 | 08/08/06 | Measurement of entrained and dissolved gasesin process flow lines |

| 7,096,719 | 08/29/06 | Apparatus for measuring parameters of a flowing multiphase mixture |

| 7,110,893 | 09/19/06 | Method and apparatus for measuring a parameter of a fluid flowing within a pipe using an array of sensors |

| 7,121,152 | 10/17/06 | A portable flow measurement apparatus having an array of sensors |

| 7,123,833 | 10/17/06 | Dynamically reconfigurable optical smart node |

| 7,124,818 | 10/24/06 | Multiple Component Sensor Mechanism |

| 7,126,740 | 10/24/06 | Multifunctional optical device having a spatial light modulator with an array of micromirrors. |

| 7,127,360 | 10/24/06 | Dual function flow measurement apparatus having an array of sensors |

| 7,134,320 | 11/14/06 | Apparatus and method for providnig a density measurement augmented for entrained gas |

| 7,139,667 | 11/21/06 | Method for calibrating a volumetric flow meter having an array of sensors |

| 7,146,864 | 12/12/06 | An apparatus having a multiband sensor assembly for measuring a paramenter of a fluid flow flowing within a pipe |

| 7,150,202 | 12/19/06 | Method and apparatus for measuring characteristics of core-annular flow |

| 7,152,003 | 12/19/06 | Method and apparatus for determining a quality metric of a measurement of a fluid parameter |

| 7,152,460 | 12/26/06 | An apparatus and method for compensating a coriolis meter |

| 7,155,074 | 12/26/04 | A pressure transducer featuring large diameter configured for reducing the bulk modulus of compressibility thereof |

| 7,165,464 | 01/23/07 | An apparatus and method for providing a flow measurement compensated for entrained gas |

| 7,171,315 | 01/30/07 | Method and apparatus for measuring a parameter of a fluid flowing within a using sub-array processing |

| 7,180,601 | 02/20/07 | Optical system featuring chirped Bragg Grating Etalon for providing precise reference wavelengths |

| 7,181,955 | 02/27/07 | Apparatus and method for measuring multi-phase flows in pulp and paper industry applications |

| 7,197,938 | 04/03/07 | Contact-based transducers for charactarizing unsteady pressures in pipes |

| 7,197,942 | 04/03/07 | Apparatus for measuring velocity and flow rate of a fluid having a non-negligible axial mach number using an array of sensors |

| 7,209,606 | 04/24/07 | A Fabry-Perot Element Based on a Large-Diameter Optical Waveguide |

| 7,237,440 | 07/03/07 | A flow measurement apparatus having strain-based sensors and ultrasonic sensors |

| 7,245,385 | 07/17/07 | Characterizing unsteady pressures in pipes using optical measurement devices |

| 7,253,742 | 08/07/07 | Method and apparatus for measuring parameters of a fluid flowing within a pipe using a configurable array of sensors |

| 7,253,897 | 08/07/07 | Optical spectrum analyzer |

| 7,261,002 | 08/28/07 | Flow rate measurement using unsteady pressures |

| 7,269,316 | 09/11/07 | Method for restoring or increasing photosensitivity in hydrogen or deuterium loaded large diameter optical waveguide |

| 7,275,421 | 10/02/07 | Apparatus and method for measuring parameters of a mixture having solid particules suspended in a fluid flowing in a pipe |

| 7,295,933 | 11/13/07 | Configurable multi-function flow measurement apparatus having an array of sensors |

| 7,299,705 | 11/27/07 | An apparatus and method for augmenting a coriolis meter |

| 7,302,861 | 12/04/07 | A portable flow measurement apparatus having an array of sensors |

| 7,308,820 | 12/18/07 | Piezocable based sensor for measuring unsteady pressures inside a pipe |

| 7,322,245 | 01/29/08 | Apparatus and method for measuring a fluid flowing in a pipe using acoustic pressures |

| 7,322,251 | 01/29/08 | Method and apparatus for measuring a parameter of a high temperature fluid within a pipe using an array of piezoelectric based flow sensors |

| 7,328,113 | 02/05/08 | Method for calibrating a volumetric flow meter having an array of sensors |

| 7,328,624 | 02/12/08 | Probe for Measuring Parameters of a Flowing Fluid and/or Multiphase Mixture |

| 7,330,797 | 02/12/08 | An Apparatus and Method for Measuring Settlement of Solids in a Multiphase Flow |

| 7,337,075 | 02/26/08 | Apparatus and Method for Measuring Parameters Of A Mixture Having Liquid Droplets Suspended in A Vapor Flowing In A Pipe |

| 7,340,353 | 03/04/08 | A dual function flow measurement apparatus having an array of sensors |

| 7,343,818 | 03/18/08 | A clamp on apparatus and method for measuring gas volume fraction of a gluid flowing within a pipe |

| 7,343,820 | 03/15/08 | An apparatus and method for fiscal measuring of an aerated fluid |

| 7,359,803 | 04/15/08 | Apparatus and method for measuring parameters of a mixture having solid particles suspended in a fluid flowing in a pipe |

| 7,363,800 | 04/29/08 | Apparatus and method for measuring compositional parameters of a mixture |

| 7,367,239 | 05/06/08 | Piezocable based sensor for measuring unsteady pressures inside a pipe |

| 7,367,240 | 05/06/08 | An apparatus and method for providing a flow measurement compensated for entrained gas |

| 7,369,716 | 05/06/08 | High pressure and high temperature acoustic sensor |

| 7,379,828 | 05/27/08 | Method for determining a speed of sound quality metric for a flow meter having an array of sensors |

| 7,380,438 | 06/03/08 | Apparatus and method for providing a fluid cut measurement of a multi-liquid mixture compensated for entrained gas |

| 7,380,439 | 06/03/08 | An apparatus and method for compensating a coriolis meter |

| 7,386,204 | 06/10/08 | Optical filter having a shaped filter function |

| 7,389,187 | 06/17/08 | Apparatus and method using an array of ultrasonic sensors for determining the velocity of a fluid within a pipe |

| 7,389,687 | 06/24/08 | System for measuring a parameter of an aerated multi-phase mixture flowing in a pipe |

| 7,400,985 | 07/15/08 | An apparatus having an array of clamp on piezoelectric film sensors for measuring parameters of a process flow within a pipe |

| 7,418,877 | 09/02/08 | Wet gas metering using a differential pressure based flow meter with a sonar based flow meter |

| 7,426,852 | 09/23/08 | Submersible meter for measuring a parameter of gas hold-up of a fluid |

| 7,430,881 | 10/07/08 | Method of making an optical fiber attachment device |

| 7,430,924 | 10/07/08 | Flow measurement apparatus having strain-based sensors and ultrasonic sensors |

| 7,437,043 | 10/14/08 | Large diameter optical waveguide, grate and laser |

| 7,437,946 | 10/21/08 | An apparatus and method for measuring a parameter of a multiphase flow |

| 7,440,873 | 10/21/08 | An apparatus and method of processing data to improve the performance of a flow monitoring system |

| 7,454,981 | 11/25/08 | Apparatus and method for determining a parameter in a wet gas flow |

| 7,463,828 | 12/09/08 | Optical channel monitor |

| 7,474,966 | 01/06/09 | An apparatus having an array of piezoelectric film sensors for measuring parameters of a process flow within a pipe |

| 7,503,227 | 03/17/09 | Method and apparatus for measuring parameters of a fluid flow using an array of sensors |

| 7,516,024 | 04/07/09 | Method and apparatus for measuring parameters of a stratified flow |

| 7,526,966 | 05/05/09 | An apparatus and method for measuring a parameter of a multiphase flow |

| 7,571,633 | 08/11/09 | Measurement of entrained and dissolved gases in process flow lines |

| 7,587,948 | 09/15/09 | Flow Rate Measurement for industrial sensing applications using unsteady pressures |

| 7,596,987 | 10/06/09 | Apparatus and Method for Providing a Density Measurement Augmented for Entrained Gas |

| 7,603,916 | 10/20/09 | Wet Gas Metering using a Differential Pressure and a Sonar Based Flow Meter |

| 7,617,716 | 11/17/09 | Total Gas Meter Using Speed of Sound and Velocity Measurements |

| 7,623,976 | 11/24/09 | System of Distributed Configurable Flowmeters |

| 7,624,650 | 12/01/09 | Apparatus and Method for Attenuating Acoustic Waves Propagating within a Pipe Wall |

| 7,624,651 | 12/01/09 | Apparatus and Method for Attentuating Acoustic Waves in Pipe Walls for Clamp-On Ultrasonic Flow Meter |

| 7,657,392 | 02/02/10 | Method and Apparatus for Detecting and Characterizing Particles in a Multiphase Fluid |

| 7,661,302 | 02/16/10 | Multi-Phase Flow Measurement Ssytem having a Fluid Separator |

| 7,672,794 | 03/02/10 | System and Method for Operating a Flow Process |

| 7,673,526 | 03/09/10 | Method and Apparatus for Measuring a Paramter of a Fluid Flowing Within a Pipe Having a Sensing Device with Multiple Sensor Segments |

| 7,690,266 | 04/06/10 | Process Fluid Sound Speed Determined by Characterization of Acoustic Cross Modes |

| 7,725,270 | 05/25/10 | Industrial Flow Meter Having an Accessible Digital Interface |

| 7,752,918 | 07/13/10 | Apparatus and Method for Measuring a Fluid Flow Parameter within an Internal Passage of an Elongated Body |

| 7,793,555 | 09/14/10 | Apparatus and Method for Augmenting a Coriolis Meter |

| 7,810,400 | 10/12/10 | Velocity Based Method for Determining Air-fuel Ratio of a Fluid Flow |

| 7,831,398 | 11/09/10 | Method for Quantifying Varying Propagation Characteristics of Normal Incident Ultrasonic Signals as used in Correlation Based Flow Measurement |

| 7,882,750 | 02/08/11 | Method and Apparatus for Measuring Parameters of a Fluid Flowing within a Pipe Using a Configurable Array of Sensors |

| 7,962,293 | 06/14/11 | Apparatus and Method for Providing a Stratification Metric of a Multiphase Fluid Flowing within a Pipe |

| 7,963,175 | 06/21/11 | Clamp-On Apparatus for Measuring a Fluid Flow That Includes a Protective Sensor Housing |

| 7,963,177 | 06/21/11 | Apparatus for Attenuating Ultrasonic Waves Propagating Within a Pipe Wall |

| 7,795,559 | 07/14/11 | Apparatus for Attenuating Ultrasonic Waves Propagating within a Pipe Wall |

| 8,061,186 | 11/22/11 | System and Method for Providing a Compositional Measurement of a Mixture Having Entrained Gas |

| 8,109,127 | 02/07/12 | Measurement of Entrained and Dissolved Gases in Process Flow Lines |

| 8,117,918 | 02/21/12 | Method and Apparatus for Determining Pipewall Thickness Using One or More Ultrasonic Sensors |

| 8,228,686 | 07/24/12 | Apparatus and Method for Measuring Liquid and Gas Flow Rates in a Stratified Multi-Phase Flow |

| 8,286,466 | 10/16/12 | Method and Apparatus for Making a Water Cut Determination Using a Sequestered Liquid-Continuous Stream |

| 8,336,393 | 12/25/12 | Method and Apparatus for Measuring Parameters of a Fluid Flowing within a Pipe Using a Configurable Array of Sensors |

| 8,346,491 | 01/01/13 | Sonar-Based Flow Meter Operable to Provide Product Identification |

| 8,402,840 | 03/26/13 | Ultrasonic Fluid Flow Meter Housing with Acoustically Matched Base |

| 8,402,841 | 03/26/13 | Apparatus and Method for Sensing Fluid Flow in a Pipe with Variable Wall Thickness |

| 8,428,892 | 04/23/13 | Viscous Fluid Flow Measurement Using a Differential Pressure Measurement and a Sonar Measured Velocity |

| 8,452,551 | 05/28/13 | Method and Apparatus for Monitoring Multiphase Fluid Flow |

| 8,641,813 | 02/04/14 | System and Method for Optimizing a Gas/Liquid Separation Process |

| 8,713,988 | 05/06/14 | Use of Gas Void Fraction Measurement is the Closed Loop Control of a Fermentation Process |

| 8,739,637 | 06/03/14 | Applications for Real-Time Mass Ratio, Mass Flow and Particle Size Measurement of Particle Laden Flows |

| 8,862,411 | 10/14/14 | Velocity and Impingement Method for Determining Parameters of a Particle/Fluid Flow |

| 8,893,558 | 11/25/14 | Method and Apparatus for Measuring Parameters of a Fluid Flowing Within a Pipe Using a Configurable Array of Sensors |

| 8,931,520 | 01/13/15 | Pipe with Integrated Process Monitoring |

| 9,046,399 | 06/02/15 | Minimally Intrusive Monitoring of a Multiphase Process Flow Using a Tracer and a Spatially Arranged Array of at Least Two Sensors on a Flow Pipe |

| 9,057,635 | 06/16/15 | Velocity Based Method for Determining Air-Fuel Ratio of a Fluid Flow |

| 9,062,682 | 06/23/15 | Applications of Pump Performance Monitoring |

| 9,068,872 | 06/30/15 | Method and Apparatus for Monitoring Multiphase Fluid Flow |

| 9,169,158 | 10/27/15 | Non-Chemical Air Entrained Admix |

| 9,291,490 | 03/22/16 | Applications of Sonar-Based VF/GVF Metering to Industrial Processing |

| 9,297,733 | 03/29/16 | Dispersion Compensation Technique for Differential Sonar Measurement – Density Meter |

| 9,302,270 | 04/05/16 | Mineral Separation Using Functinalized Filters and Membranes |

| 9,327,294 | 05/03/16 | Synthetic Bubbles or Beads Having Hydrophobic Surface |

| 9,335,298 | 05/10/16 | Wear-Monitoring with Rotational Sensor and Sensor Thickness |

| 9,352,335 | 05/31/16 | Synthetic Beads/Bubbles Functionalized with Molecules for Attracting and Attaching to Mineral Particles of Interest |

| 9,360,309 | 06/07/16 | Method and Apparatus for Monitoring of Component Housing Wall Thickness and Wear Monitoring |

| 9,366,653 | 06/14/16 | Graphical User Interace Re Wear Monitoring |

| 9,404,893 | 08/02/16 | Flow and Pipe Management Using Velocity Profile Measurement and/or Pipe Wall Thickness and Wear Monitoring |

| 9,612,194 | 04/04/17 | Spectroscopic Analysis of Oil Sands Ore Face for Real Time Ore Blend Management |

| 9,645,001 | 05/09/17 | Performance Monitoring of Individual Hydroclones Using Sonar-Based Slurry Flow Measurement |

| 9,696,190 | 07/04/17 | Acoustic Probing Technique for the Determination of Multiple Liquid/Froth Interfaces in Separation and Storage Vessels Based on an Oblique Tomographic Analysis Approach |

| 9,731,221 | 08/15/17 | Apparatus Having Polymer Surfaces Having a Siloxane Functional Group |

| 9,759,556 | 09/12/17 | Acoustic Probing Technique for the Determination of Interior Pipe Coating Wea or Scale Build-Up and Liner Wear |

| 9,810,665 | 11/07/17 | Sonic Filter for Measuring and Capturing Particles Having a Particular Particle Size in a Fluid, Mixture or Process Flow |

| 9,827,574 | 11/28/17 | Mineral Separation Using Sized-, Weighted- or Magnetic-Based Polymer Bubbles or Beads |

| 9,833,763 | 12/05/17 | Optimizing Acoustic Efficiency of a Sonic Filter or Separator |

| 9,839,919 | 12/12/17 | Charged Engineered Polymer Beads/Bubbles Functionalized with Molecules for Attracting and Attaching to Mineral Particles of Interest for Flotation Separation |

| 9,851,201 | 12/26/17 | Method and Apparatus for Using Cepstrum and Wavelet Based Algorithms for Wall Thickness Measurement |

| 9,880,095 | 01/30/18 | Laser Based System for Bitumen Content Determination, E.G., Using Discrete Wavelength Spectroscopic Analysis |

| 9,909,910 | 03/06/18 | Tomographic and Sonar-Based Processing Using Electrical Probing on a Flowing Fluid to Determine Flow Rate |

| 9,921,092 | 03/20/18 | Velocity Based Method for Determining Air-Fuel Ratio of a Fluid Flow |

| 9,932,525 | 04/03/18 | Method and System for Flotation Separation in a Magnetically Controllable and Steerable Medium |

| 9,943,860 | 04/17/18 | Mineral Recovery in Tailings Using Functionalized Polymers |

| 9,977,007 | 05/22/18 | Bubble Size Determination Based on Bubble Stiffness |

| 9,981,271 | 05/29/18 | Method and System for Releasing Mineral from Synthetic Bubbles and Beads |

| 9,981,272 | 05/29/18 | Techniques for Transporting Synthetic Beads or Bubbles in a Flotation Cell Or Column |

| 9,989,453 | 06/05/18 | Tomographic Determination of Scale Build-Up in Pipes and Other Tanks, Cells, Vessels or Containers |

| 9,995,609 | 06/12/18 | Single Wrapped Sensor Flow Meter |

| 10,031,009 | 07/24/18 | Flow Profiling Techniques Based on Modulated Magnetic Electrical Impedance Tomography |

| 10,060,570 | 08/28/18 | Smart Pipe Concept Based on Embedded Taggant-Sensor and/or Color-Encoded Elements to Monitor Liner Wear in Lined Pipelines, Incluing Uethan Lined Pipe |

| 10,071,352 | 09/11/18 | Techniques for Agglomerating Mature Fine Tailing by Injecting a Polymer in a Process Flow |

| 10,088,454 | 10/02/18 | Speed of Sound and/or Density Measurement Using Acoustic Impedance |

| 10,099,251 | 10/16/18 | Re-Lined Pipe Technique for Wear Mitigation in Slurry Transport Pipeline |

| 10,156,547 | 12/18/18 | Method and Appartaus for Providing Real Time Air Measurement Applications in Wet Concrete |

| 10,216,204 | 02/26/19 | Determining Shear Rate and/or Shear Stress from Sonar Based Velocity Profiles and Differential Pressure |

| 10,228,706 | 03/12/19 | Method and Apparatus for Using Velocity Profile Measurements in Recovering Bitumen from a Coarse Tailings Line |

| 10,245,597 | 04/02/19 | Dimensionally Controlled “Engineered Polymer Bubble” for Flotation Separation |

| 10,309,887 | 06/04/19 | Acoustic Impact Particle Size Measurement |

| 10,357,782 | 07/23/19 | Flotation Separation Using Lightweight Synthetic Beads or Bubbles |

| 10,379,071 | 08/13/19 | Dual Acoustic and Electrical Analysis Technique for the Tomographic Determination of Multiphase Flows in Pipes and/or Liquid/Froth Interfaces in Process Tanks |

If you have any questions regarding CiDRA’s patents please contact CiDRA at the below address.

CiDRA

50 Barnes Park North

Wallingford, CT 06492

Attn: Patents

Phone: 203.265.0035

Fax: 203.294.4211

email CiDRA Patents

This page was last updated: August 14, 2019